business resources

Choosing the Right Industrial Sump Pump for Your Facility: Here’s How

16 Nov 2024, 7:44 pm GMT

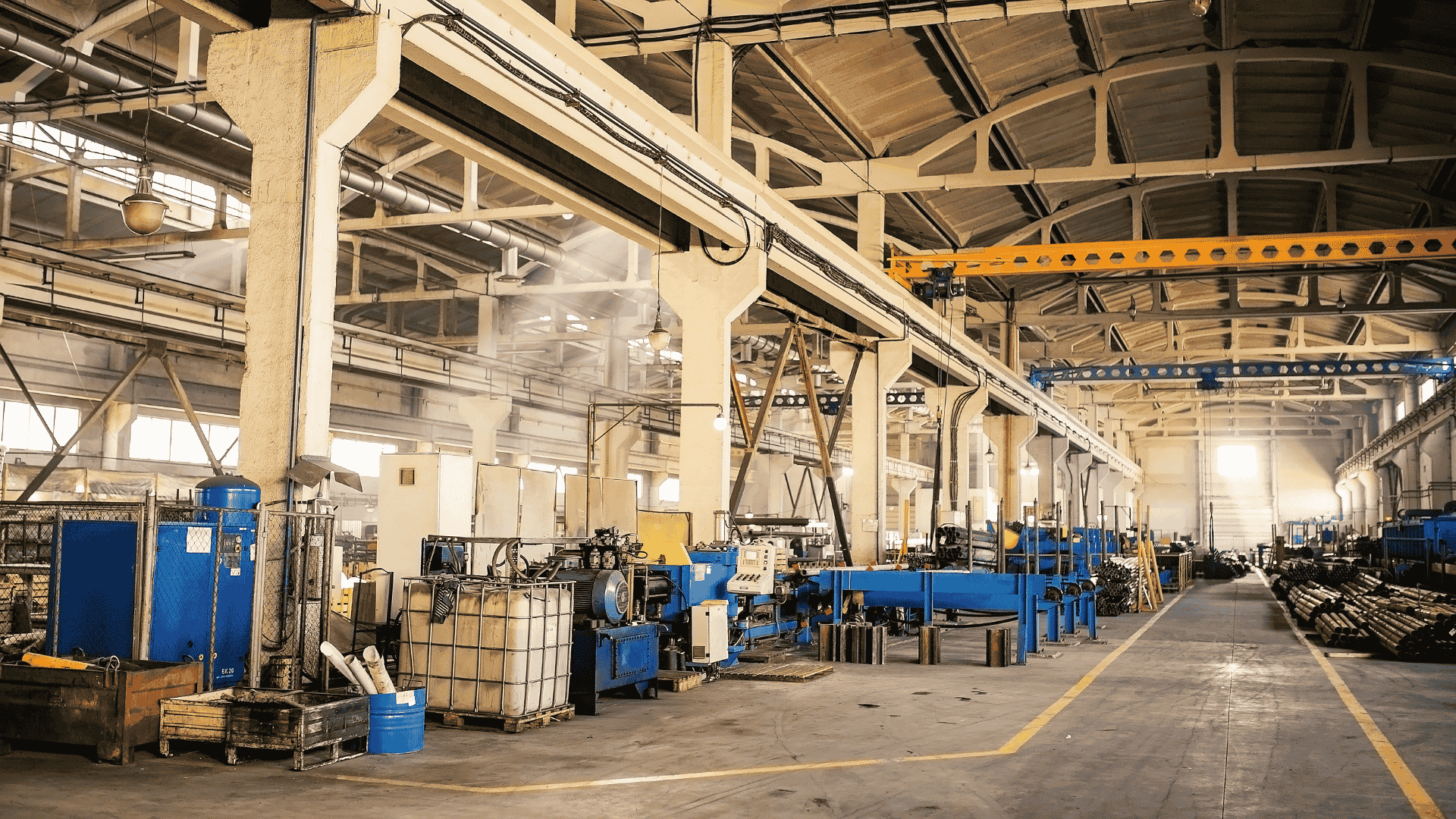

When it comes to keeping industrial facilities safe from flooding and water damage, sump pumps play a crucial role. Choosing the right sump pump for your facility requires understanding the different types, capacities, materials, and features available to ensure efficient water management and reduced maintenance. Here’s a guide on selecting the ideal industrial sump pump for your facility.

1. Types of Industrial Sump Pumps

Selecting the right sump pump starts with understanding the available types. Each sump pump type is designed to address specific water management needs and comes with varying levels of capacity and power. The primary types of reliable sump pumps include submersible sump pumps, pedestal sump pumps, and effluent pumps. Submersible Sump Pumps are positioned below the waterline, these pumps are fully submerged in the sump basin, making them quieter and more efficient for deep pits. They are ideal for applications that require high water capacity removal. Pedestal Sump Pumps are sitting above the waterline with an elevated motor, pedestal pumps are easier to maintain and inspect but are typically louder. They are suitable for shallower basins and where the water removal needs are less intensive. Effluent Pumps are designed to handle waste in addition to water, effluent pumps are commonly used in applications where light solids, such as dirt or sand, are present in the water. This type is often used in septic systems or areas with minor debris in the water.

Each type offers different advantages, so understanding the nature of your water management needs is essential when selecting a reliable sump pump for your facility.

2. Determining the Pump Capacity Needed

Industrial facilities often require pumps with high capacity to quickly remove water and prevent flooding. Pump capacity is typically measured in gallons per minute (GPM), which indicates how much water the pump can move within a minute. When determining the right capacity, consider factors such as the size of the facility, the amount of water accumulation, and the pump’s intended location.

A high-capacity sump pump is essential for facilities prone to heavy water infiltration, such as factories with below-ground levels or areas with high rainfall. Conversely, smaller facilities or spaces with minimal water accumulation may need less capacity. Always consider the worst-case scenario to ensure that your sump pump is adequately equipped to handle heavy water flows.

3. Considering Pump Materials and Durability

Industrial sump pumps must withstand harsh environments, including exposure to chemicals, debris, and varying temperatures. Therefore, the materials used in a pump's construction play a significant role in its durability and lifespan. Common materials for industrial sump pumps include:

- Cast Iron: Known for its durability, cast iron is highly resistant to corrosion and can handle rough conditions, making it ideal for industrial environments.

- Stainless Steel: This material is corrosion-resistant and lightweight, offering long-term durability in facilities where chemical exposure is common.

- Thermoplastic: While lightweight and corrosion-resistant, thermoplastic is best suited for lighter-duty applications.

Investing in a pump made from high-quality materials ensures that it can withstand the facility's environment, reducing the need for frequent repairs and extending its operational life.

4. Evaluating Power and Electrical Requirements

Since industrial sump pumps often handle high volumes of water, they require more power than standard residential pumps. Electrical requirements can vary, but most industrial models need a 220V or 230V power supply to operate efficiently. For facilities with higher water demands, a three-phase pump motor may provide additional power and efficiency compared to single-phase options.

Additionally, consider whether your facility requires a backup power source. During heavy storms or power outages, a battery-operated backup pump ensures that water is still managed effectively, reducing the risk of flooding. Facilities that rely on continuous operation should prioritize a sump pump with an integrated or compatible backup power solution.

5. Maintenance and Serviceability Considerations

Routine maintenance is essential for prolonging the life of an industrial sump pump. Factors that affect serviceability include the pump’s placement, accessibility, and ease of part replacement. For instance, submersible pumps require the pump to be pulled from the basin for servicing, while pedestal pumps offer easier access due to their above-water positioning.

Choose a sump pump model that allows for straightforward maintenance and has readily available replacement parts. This will help minimize downtime and repair costs. Additionally, some manufacturers offer service plans or warranties, which can be beneficial for maintaining consistent pump performance and avoiding unexpected repair expenses.

Choosing the right industrial sump pump is essential for managing water effectively and safeguarding your facility against potential damage. By evaluating pump types, capacity, materials, power requirements, automation features, and maintenance needs, you can select a pump that meets your facility’s unique requirements. A well-chosen industrial sump pump not only improves operational efficiency but also provides peace of mind, knowing your facility is protected from unexpected water hazards.

Share this

Arthur Brown

Writer

A dad of 3 kids and a keen writer covering a range of topics such as Internet marketing, SEO and more! When not writing, he's found behind a drum kit.

previous

Unlocking Opportunity: Exploring the Top Properties in Turkey for Investment and Their Impact on Business Growth

next

Why Remote Healthcare is the Next Big Career Move for Medical Professionals