business resources

Critical Considerations in Selecting a CNC Machining Service

21 Sept 2023, 6:48 pm GMT+1

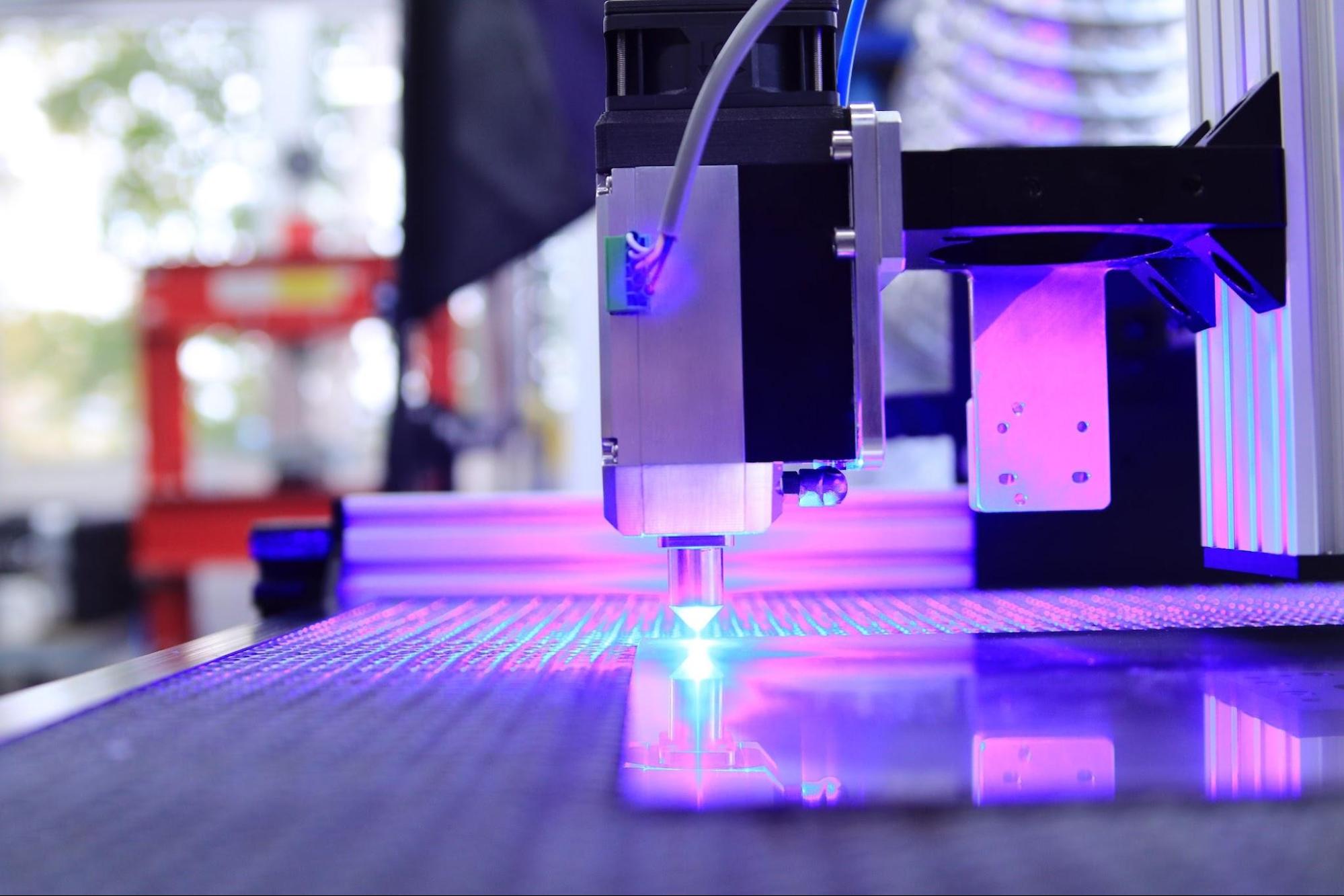

In the contemporary manufacturing landscape, computer numerical control (CNC) machining stands out as the solution for precision and efficiency. In a nutshell, CNC machining has become an essential instrument across various sectors, from aerospace engineering to automotive design and groundbreaking medical technologies.

A study by Fortune Business Insights, as cited in GlobeNewswire, indicated that the global CNC machine market, valued at USD 83.99 billion in 2021, is anticipated to reach an impressive USD 140.78 billion by 2029. This substantial growth is driven by the imperative for precision in intricate machining products and a rising inclination towards mass customization.

As the manufacturing domain broadens, there's an influx of CNC machining services entering the market. The real challenge is discerning and selecting the most adept service. This article delves into the paramount factors that should guide such a pivotal decision:

Proficiency and Tenure: The Cornerstones of CNC Machining

In the field of CNC machining services, longevity, and expertise serve as reliable indicators of a company's prowess. The duration a service provider has sustained in this ever-evolving sector signifies more than just time—it epitomizes their adaptability, resilience, and mastery. It's a testament to their journey, marked by diverse projects, surmounted challenges, and innovative strides.

For instance, 3ERP Inc. offerings transcend mere solutions; they exemplify the integral role of technical proficiency and extensive experience in CNC machining. With a strong reputation for consistently delivering premium products and services, 3ERP has established itself as a benchmark in the industry. Their commitment to surpassing client expectations, even amidst complex projects, accentuates their deep understanding of CNC machining nuances.

Their rich experience equips them to devise customized solutions tailored to the unique challenges of their clientele. With a philosophy anchored in continuous growth and adaptation, 3ERP remains at the forefront, pioneering unparalleled quality and operational efficiency.

Whether it's a nascent startup envisioning a prototype or an established enterprise preparing for mass production, 3ERP's amalgamation of profound experience and avant-garde technical expertise makes them a preferred choice for many industry leaders.

Machinery and Technological Advancements: The Confluence of Precision and Innovation

Modern CNC machines, equipped with intricate calibrations and state-of-the-art features, have the capability to sculpt raw materials into precision-engineered products. However, the essence of this creation lies in the synergy between the machinery and the software that powers it. The integration of contemporary CAD/CAM technologies orchestrates this synergy, ensuring flawless execution.

A service provider's proclivity to remain abreast of technological innovations and adeptly incorporate them into their operations is indicative of their progressive approach.

Material Diversity and Flexibility: The Foundation of Craftsmanship

Furthermore, industry leaders often collaborate with suppliers who consistently provide top-tier materials, ensuring a seamless flow for manufacturing processes. One such reputed supplier in the arena is Wistex. Their commitment to quality and extensive material expertise makes them an invaluable asset for CNC machining services aiming for excellence and precision in every project.

Such services not only proffer an extensive array of material options but also ensure that each material adheres to the highest quality standards, is ethically sourced, and is accompanied by certifications vouching for its genuineness.

Uncompromising Quality Assurance: The Hallmark of Distinction

CNC machining services are very careful when it comes to quality assurance, as their business depends on their guarantee of quality. The best services guarantee that every creation will endure both time and meticulous examination. And that’s exactly why premier CNC machining services integrate quality assurance throughout their operational processes. From preliminary design discussions to final quality checks, their dedication remains unyielding with the aim of satisfying clients.

They adopt stringent testing methodologies, leverage cutting-edge inspection instruments, and cultivate an ethos of perpetual enhancement, ensuring that every product epitomizes their commitment to excellence.

Conclusion

The future of manufacturing transcends machinery and materials—it encapsulates vision, innovation, and an unwavering quest for excellence.

As industries evolve and the demand for precision rises, the selection of a CNC machining service becomes increasingly consequential.

This choice can influence project trajectories, mold innovations, set new industry benchmarks, and, of course, give businesses a serious competitive edge. By prioritizing experience, technological integration, material diversity, and an unwavering commitment to quality, businesses can ensure they're aligning with not just a service provider but a strategic partner in their pursuit of manufacturing brilliance.

Share this

Contributor

Staff

The team of expert contributors at Businessabc brings together a diverse range of insights and knowledge from various industries, including 4IR technologies like Artificial Intelligence, Digital Twin, Spatial Computing, Smart Cities, and from various aspects of businesses like policy, governance, cybersecurity, and innovation. Committed to delivering high-quality content, our contributors provide in-depth analysis, thought leadership, and the latest trends to keep our readers informed and ahead of the curve. Whether it's business strategy, technology, or market trends, the Businessabc Contributor team is dedicated to offering valuable perspectives that empower professionals and entrepreneurs alike.

previous

8 Degrees to Consider with Experience in Call Centres

next

Advantages of Direct Mail Marketing