business resources

Harnessing Efficiency and Innovation: A Deep Dive into Injection Moulding vs 3D Printing Startup Costs

8 Feb 2024, 11:46 am GMT

In the rapidly evolving world of manufacturing technologies, understanding the financial implications of Injection Moulding and 3D Printing is paramount for businesses looking to harness efficiency and innovation. This exploration offers a comprehensive analysis of startup costs associated with these two pivotal manufacturing techniques, providing insights that could shape future investment and operational decisions.

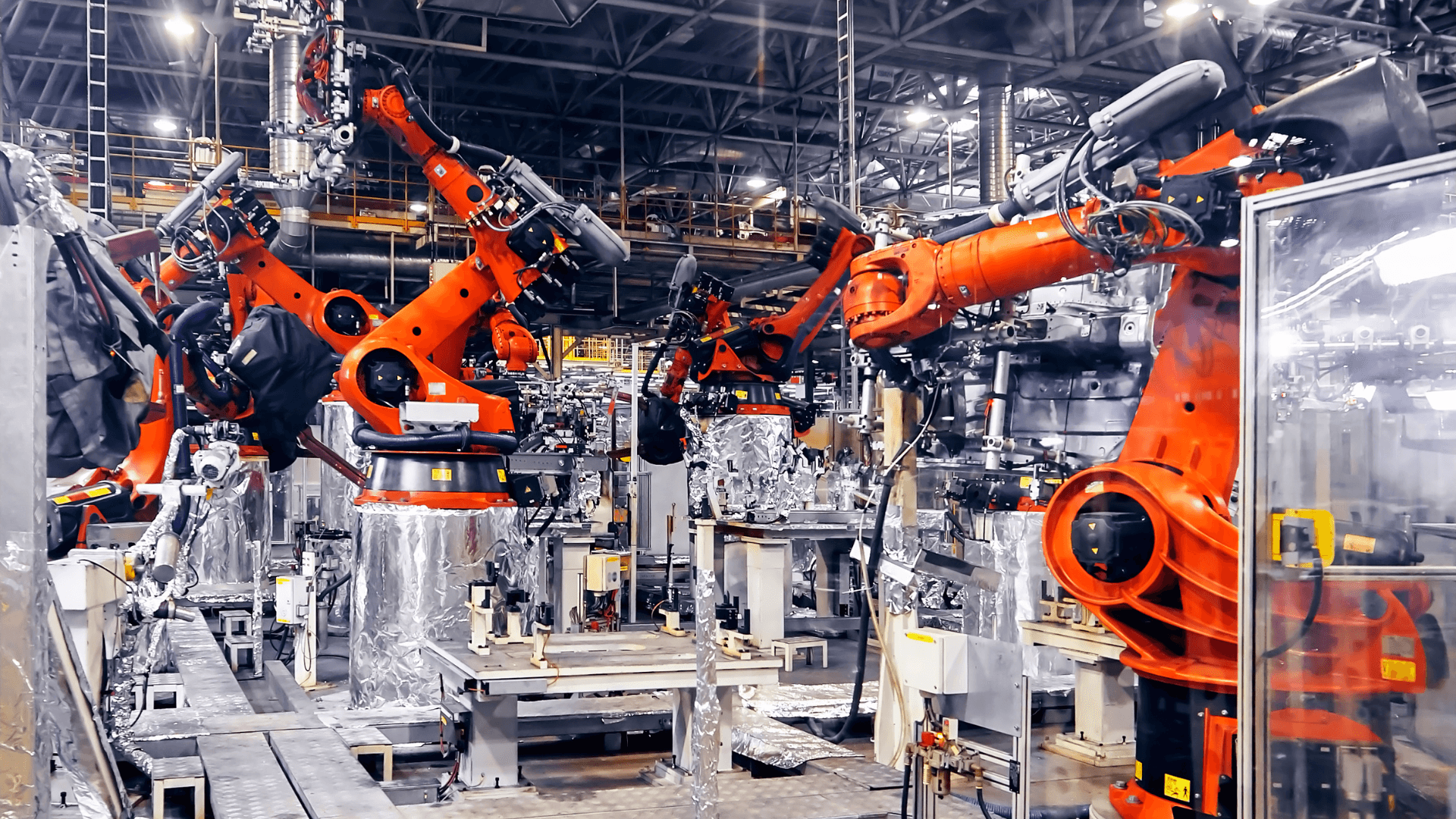

The manufacturing landscape has witnessed a seismic shift with the advent of Injection Moulding and 3D Printing—two technologies that have revolutionized how products are designed, developed, and delivered. Injection Moulding, a traditional method, excels in mass production, offering unparalleled speed and precision for high-volume orders. Conversely, 3D Printing, a beacon of the fourth industrial revolution, brings the promise of customization, complexity, and rapid prototyping with reduced lead times. Understanding the startup costs involved in both methods is crucial for manufacturers to make informed decisions that align with their operational goals and budget constraints.

What is Injection Moulding?

Basics of Injection Moulding Process

Injection Moulding is a manufacturing process for producing parts by injecting molten material into a mould. It is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars.

- Designing the mould

- Choosing the material

- Melting the material

- Injecting the material into the mould

- Cooling and solidifying the material

- Ejecting the finished product

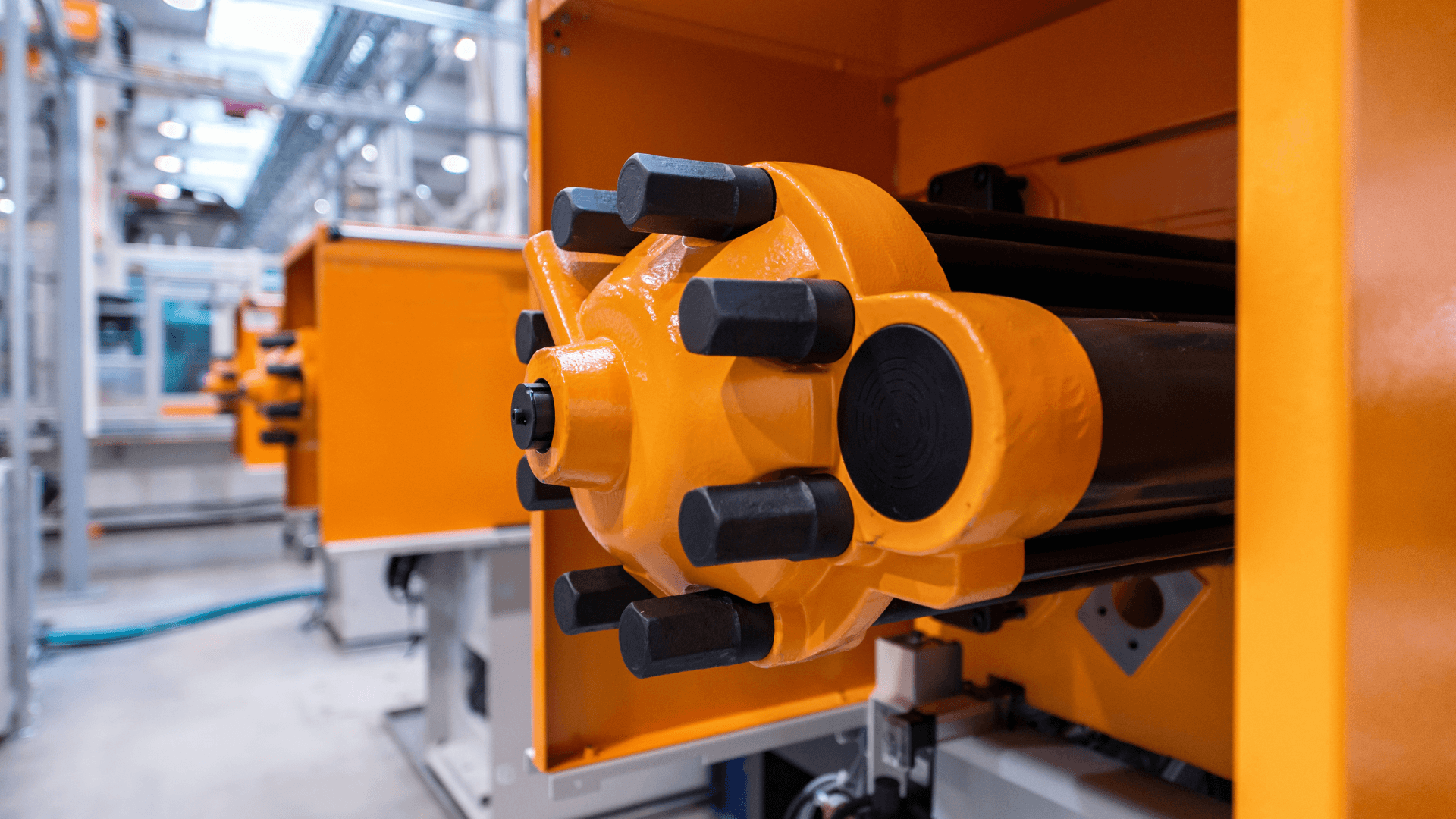

Key Components of an Injection Moulding Machine

Understanding the machinery involved in Injection Moulding is key to comprehending its startup costs. The main components include:

- Injection unit

- Clamping unit

- Mould

- Drive system

- Control system

Advantages of Injection Moulding

Injection Moulding offers significant advantages, particularly for large-scale production:

- High production rates

- Excellent dimensional accuracy

- Ability to use a wide range of materials

- Low labor costs per unit

- Minimal post-production finishing required

Common Applications of Injection Moulding

This process is versatile, supporting a broad spectrum of industries:

- Automotive components

- Consumer electronics

- Medical devices

- Toys

For instance, 3ERP injection molding services offerings transcend mere solutions; they exemplify the integral role of technical proficiency and extensive experience in the injection molding processes. With a strong reputation for consistently delivering premium products and services, 3ERP has established itself as a benchmark in the industry.

Their commitment to surpassing client expectations, even amidst complex projects, accentuates their deep understanding of injection molding nuances.

What is 3D Printing?

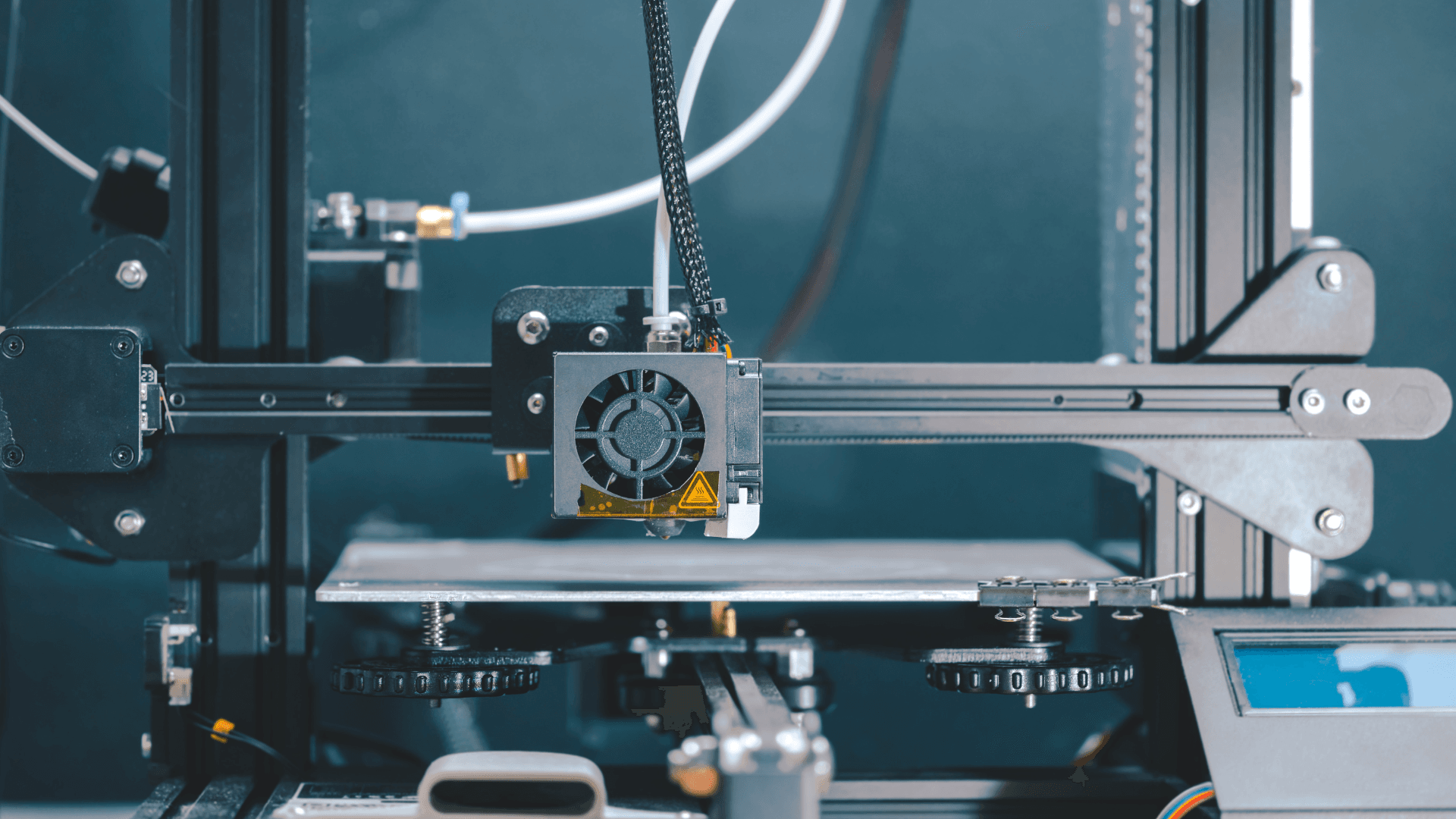

Understanding the 3D Printing Process

3D Printing, or additive manufacturing, builds objects layer by layer from a digital model. The key stages include:

- Designing the 3D model

- Preparing the printer

- Printing the object

- Post-processing

Types of 3D Printing Technologies

3D Printing encompasses various technologies, each with its unique advantages and applications:

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

Advantages of 3D Printing

3D Printing stands out for its:

- Flexibility in design

- Reduced waste

- Lower tooling costs

- Ability to produce complex geometries

Common Applications of 3D Printing

From prototypes to finished products, 3D Printing serves diverse sectors:

- Aerospace

- Healthcare

- Fashion

- Architecture

Comparing Startup Costs: Injection Moulding vs 3D Printing

Initial Investment and Setup Costs

The initial investment for Injection Moulding typically exceeds that of 3D Printing cost, primarily due to the mold design and production. In contrast, 3D Printing requires a lower initial investment, focusing on the cost of the printer and the setup.

Material Costs

Both technologies offer a range of materials, but the cost can vary significantly based on the type and quality of materials used. Injection Moulding materials are generally less expensive on a per-unit basis for large-scale production, whereas 3D Printing materials can be costlier, especially for high-quality or specialized materials.

Labor Costs

Injection Moulding tends to have higher labor costs in the design and production of moulds but lower operating labor costs. 3D Printing, meanwhile, benefits from automation, which can significantly reduce labor costs, especially for small-scale production.

Maintenance and Operational Costs

Operational costs for Injection Moulding include maintenance of the machines and the moulds, which can be substantial. 3D Printing has lower maintenance costs but can incur higher costs for machine calibration and post-processing.

How to Calculate Startup Costs for Injection Moulding?

Estimating the Cost of Mould Design and Production

Design complexity

Mould size

Material choice

Calculating Material Costs for Injection Moulding

Factors affecting material costs include:

- Type of material

- Quantity

- Market price fluctuations

Assessing Labor Costs in Injection Moulding

Considerations include:

- Design and prototype development

- Mould production

- Operation and supervision

How to Calculate Startup Costs for 3D Printing?

Estimating 3D Printer Purchase and Setup Costs

The cost varies by:

- Printer technology (FDM, SLA, SLS, etc.)

- Printer size and complexity

- Additional equipment for post-processing

Calculating Material Costs for 3D Printing

Material costs depend on:

- Material type (plastic, resin, metal)

- Quality and properties

- Quantity used per print

Labor Costs in 3D Printing Operations

The extent of automation versus manual labor can significantly influence labor costs, with higher automation leading to lower costs.

Break-Even Analysis for Injection Moulding vs 3D Printing

Performing a break-even analysis involves considering:

- Initial investment

- Variable costs per unit

- Fixed costs

- Production volume

Key factors influencing the break-even point include the scale of production and the complexity of the parts.

Case Studies: Real-World Cost Comparisons

Injection Moulding Case Study

A detailed cost analysis of a specific project can illuminate the economic dynamics of Injection Moulding, highlighting the influence of volume and design complexity on overall costs.

3D Printing Case Study

Examining a 3D Printing project provides insights into how startup costs can vary based on printer technology, material choice, and production scale.

Choosing Between Injection Moulding and 3D Printing

Factors to Consider When Making a Decision

Key considerations include:

- Production volume

- Part complexity

- Material requirements

- Lead time

Pros and Cons of Injection Moulding vs 3D Printing

A detailed comparison reveals that while Injection Moulding is cost-effective for high-volume production, 3D Printing offers flexibility and cost savings for low-volume, complex parts.

Future Trends in Manufacturing Costs

Innovations Reducing Startup Costs

Advancements in both technologies are poised to lower startup costs, making manufacturing more accessible and efficient.

Sustainability and Its Impact on Costs

Sustainable manufacturing practices can influence costs, with both technologies making strides in reducing environmental impact.

Conclusion

In conclusion, the choice between Injection Moulding and 3D Printing hinges on a detailed understanding of their startup costs. While Injection Moulding remains the go-to for high-volume production, 3D Printing is increasingly viable for complex, customized parts with lower initial volumes. As technological advancements continue to evolve, the landscape of manufacturing costs will undoubtedly shift, offering new opportunities for efficiency and innovation.

Share this

Contributor

Staff

The team of expert contributors at Businessabc brings together a diverse range of insights and knowledge from various industries, including 4IR technologies like Artificial Intelligence, Digital Twin, Spatial Computing, Smart Cities, and from various aspects of businesses like policy, governance, cybersecurity, and innovation. Committed to delivering high-quality content, our contributors provide in-depth analysis, thought leadership, and the latest trends to keep our readers informed and ahead of the curve. Whether it's business strategy, technology, or market trends, the Businessabc Contributor team is dedicated to offering valuable perspectives that empower professionals and entrepreneurs alike.

previous

Justin Hutchens Unravels The Adversarial Potential Of AI In ‘The Language of Deception’

next

Integrating ESG Strategies In Businesses: Hilton Supra Interviews Paul Sutcliffe, Director Of EVORA Global, In Citiesabc YouTube Podcast