How to Streamline Your Production with Product Assembly Services

28 Dec 2023, 2:37 pm GMT

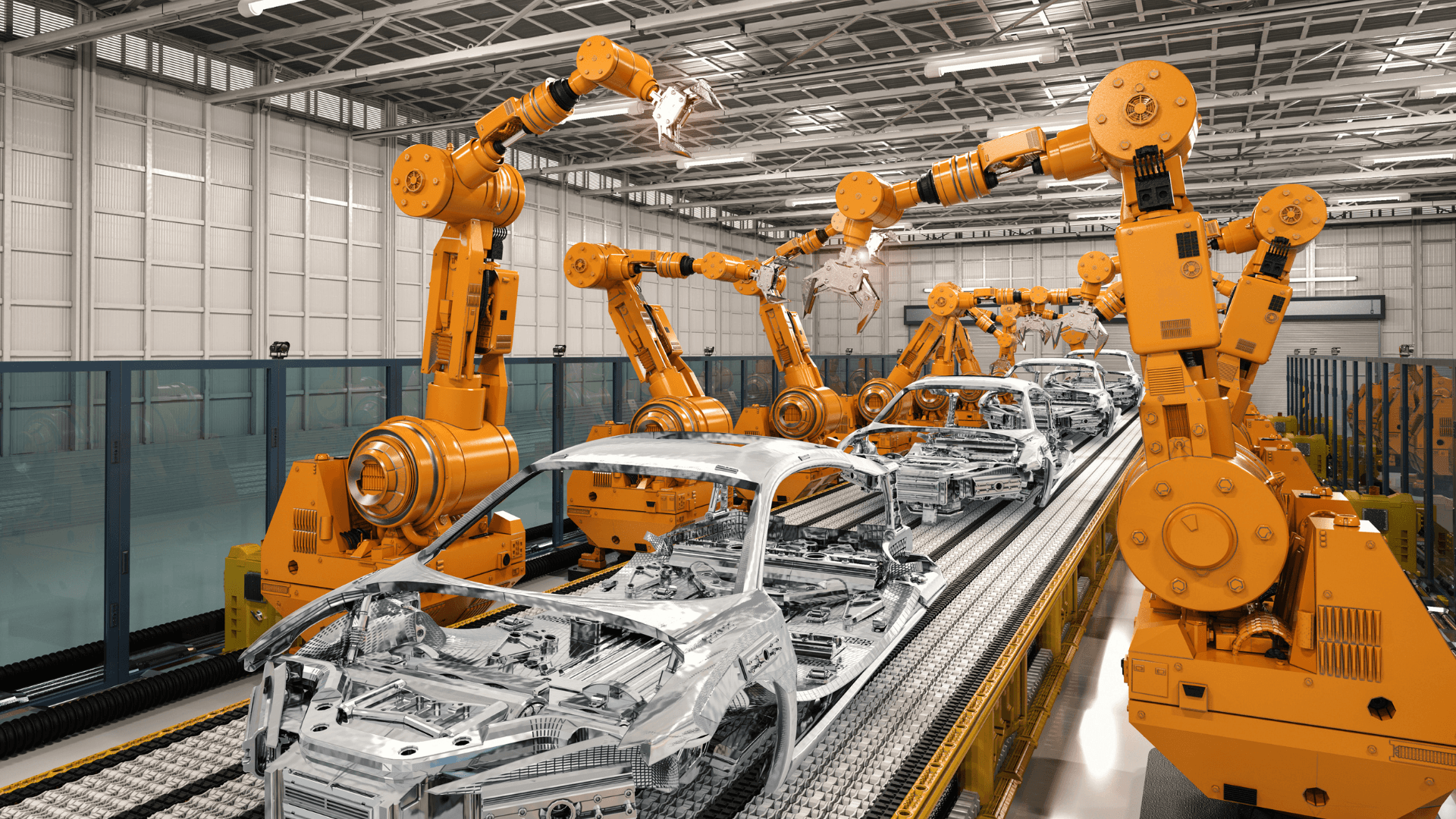

In the world of manufacturing, it's crucial for businesses to produce high-quality goods efficiently and on time to stay competitive. To achieve this, streamlining processes without compromising product quality is key. One effective way to do so is by utilizing product assembly services. These services offer a range of benefits, including cost reduction, improved efficiency, enhanced product quality, and increased customer satisfaction. This blog will explore how businesses can optimize their production processes by leveraging product assembly services.

Understanding Product Assembly Services

Product assembly services involve outsourcing the assembly process of products to companies. These companies are experts in handling assembly tasks and ensuring management throughout the entire process. They have workers, advanced equipment, and stringent quality control measures in place. Businesses can leverage their expertise to focus on their core operations while ensuring timely product assembly.

Cost Reduction

One significant advantage of using product assembly services is cost reduction. By outsourcing the assembly process, businesses can eliminate expenses associated with in-house production, such as equipment maintenance costs, hiring and training personnel for assembly tasks, and overhead expenses related to production space.

Moreover, businesses can reduce their inventory costs by focusing on maintaining materials rather than finished products.

Improved Efficiency

Product assembly services excel at optimizing efficiency in the manufacturing process. With their expertise and available resources, these service providers effectively plan workflows to minimize time wastage and increase productivity levels. Their streamlined approaches often result in the utilization of labor and equipment, ultimately leading to faster completion times for each batch of products.

IV. Enhanced Product Quality

Product quality plays a big role in satisfying customers and building a brand reputation. By collaborating with product assembly professionals who adhere to quality standards, businesses can ensure consistent excellence in the construction of their final products. These skilled assemblers are trained to handle components or follow precise instructions. Their expertise and quality checks before shipping guarantee that the final products will meet or surpass customer expectations.

V. Scalability

Adapting swiftly to market demands and efficiently expanding one's business is vital for long-term success. Assembly services offer businesses the flexibility and scalability required to achieve these goals. These service providers have established infrastructure that can accommodate fluctuating production volumes without compromising deadlines or causing bottlenecks in the manufacturing process. This level of flexibility enables businesses to respond to market demands promptly, seize growth opportunities, and avoid costs.

VI. Emphasize Core Competencies

When businesses outsource product assembly, they can focus on their core competencies without being burdened by tasks that consume time and resources. By entrusting assembly responsibilities to professionals, companies can allocate energy toward research and development innovation, marketing strategies, customer service, and other areas for business growth.

VII. Optimize the Supply Chain

In addition to the benefits, product assembly services also contribute to optimizing the supply chain. These service providers have established relationships with suppliers and distributors, which enable coordination throughout the supply chain. They seamlessly integrate their assembly processes with downstream partners, ensuring the delivery of raw materials and finished products. This optimized supply chain management helps businesses avoid delays, reduce stockouts, and enhance efficiency.

VIII. Mitigate Risks

Outsourcing product assembly can also help mitigate risks in the production process. By partnering with assembly service providers, businesses can leverage their expertise in minimizing errors or defects during assembly. These professionals are well-versed in industry practices as well as quality control measures and compliance standards. By delegating the task of assembling products to them, businesses can minimize the chances of errors that result in wasted time and resources and damage to their reputation.

Conclusion

By making use of product assembly services, businesses can gain benefits such as cost reduction, improved efficiency, enhanced product quality, and the ability to adapt production volumes according to their needs. It allows them to focus more on their core strengths. Additionally, outsourcing product assembly helps optimize the supply chain and reduces risks associated with the production process. For manufacturing companies aiming to streamline operations without compromising quality or customer satisfaction, partnering with a product assembly service provider is undoubtedly a long-term investment for success.

Share this

previous

Top Reasons Why Management Consulting Is Essential for a Startup Business

next

Understanding Volatility for Managing Risk in the Cryptocurrency Market