business resources

A Full Guide To Selecting Powerful Medium Duty Mechanical Units

15 Jan 2026, 11:45 pm GMT

Medium-duty mechanical units play a critical role across transportation, construction, agriculture, and industrial applications.

These units bridge the gap between light-duty systems and heavy industrial machinery, offering reliable performance without excessive operating demands. Selecting the right option requires attention to performance metrics, compatibility, and long-term operating needs.

A structured evaluation process helps buyers avoid mismatches that can lead to inefficiency, premature wear, or costly downtime. Understanding the core selection factors makes it easier to choose equipment that aligns with operational expectations and workload requirements.

Understanding Power Requirements and Load Demands

Power output must align with how the mechanical unit will be used daily. Medium-duty applications often involve sustained workloads rather than short bursts, making torque delivery and load stability more important than peak horsepower alone.

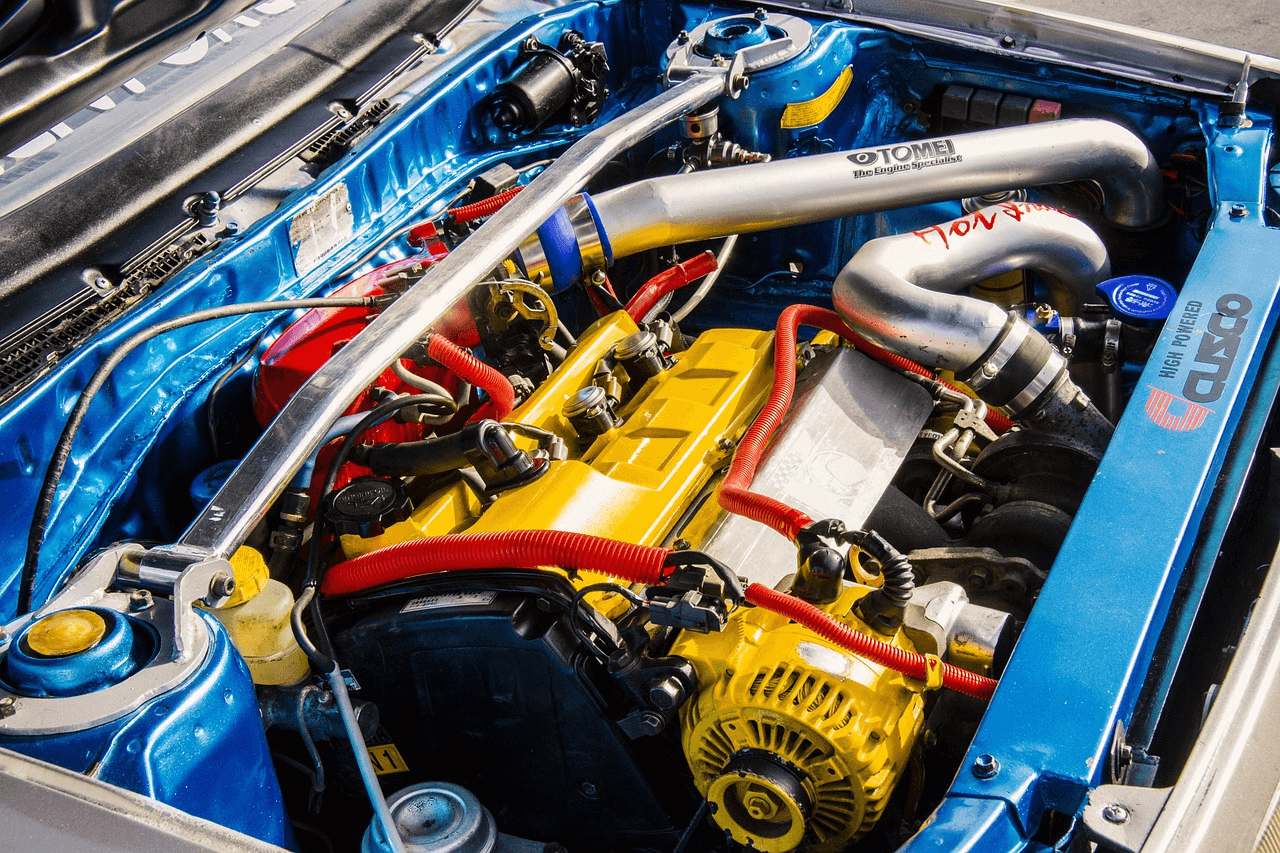

Evaluating job conditions such as hauling weight, terrain, operating hours, and auxiliary systems helps define appropriate specifications. Many buyers compare options like 8.9L Cummins ISL engines for sale when seeking balanced performance that supports steady output without overstressing internal components. Matching power delivery to real-world demands improves efficiency and reduces unnecessary strain.

Selecting too much power can increase operating costs, and underpowered systems may struggle under consistent loads.

Evaluating Torque Curves and Performance Consistency

Torque characteristics influence how well a mechanical unit performs under variable load conditions. Medium-duty systems benefit from broad torque curves that maintain output across changing speeds and workloads.

Units with consistent torque delivery handle inclines, start under load, and perform extended operation more effectively.

Reviewing torque graphs rather than headline power figures offers better insight into day-to-day usability. Performance consistency contributes directly to smoother operation and reduced component stress.

Looking at torque stability helps predict wear patterns and maintenance needs. Fluctuations in delivery can translate into vibration, heat buildup, and faster fatigue of driveline components.

For applications with frequent stop-start cycles, a flatter curve often matters more than peak output. Consistent torque supports predictable control, which operators notice immediately in responsiveness and handling.

Fuel Efficiency and Operating Economy

Fuel consumption has a direct impact on long-term ownership costs. Medium-duty units often operate for extended hours, making efficiency a critical selection factor.

Modern mechanical designs focus on optimized combustion and improved airflow to reduce waste.

Buyers should compare fuel burn rates under typical load conditions rather than relying on idealized test figures. Better fuel efficiency supports cost control and predictable operating budgets across long service intervals.

Efficiency affects refueling frequency, which matters for operations spread across large sites or long routes. Engines that maintain efficiency at partial loads tend to deliver better real-world savings than those optimized only for peak output.

Even small differences in fuel burn compound into meaningful cost gaps. Lower consumption can reduce heat and stress on components, indirectly supporting longevity. Taken together, fuel efficiency becomes both a financial and operational reliability advantage.

Durability and Internal Component Design

Durability depends on internal construction quality and material choices. Medium-duty mechanical units must withstand repeated thermal cycles, vibration, and sustained workloads.

Design elements such as reinforced blocks, hardened crankshafts, and advanced cooling pathways support longer service life.

Reviewing manufacturer specifications and service records helps identify platforms known for structural reliability. Durable construction reduces unplanned downtime and repair frequency.

Attention to bearing surfaces, piston design, and lubrication routing plays a major role in resisting wear. Components engineered for tighter tolerances tend to hold performance longer under heavy use.

Effective sealing systems help prevent contamination that can accelerate internal damage. Designs that simplify heat dissipation reduce fatigue caused by repeated expansion and contraction.

Together, these factors translate into equipment that stays reliable well beyond its nominal duty cycle.

Maintenance Accessibility and Service Support

Ease of maintenance affects both uptime and labor costs. Units designed with accessible service points simplify routine inspections and component replacement.

Key factors to review include filter placement, diagnostic access, and parts availability. Equipment that allows faster servicing minimizes operational disruption.

Buyers should think about the availability of qualified technicians and regional service coverage when comparing platforms.

Clear labeling and standardized fasteners further reduce time spent during routine service. Platforms with strong diagnostic software make troubleshooting quicker and more accurate.

Readily available service manuals and training resources help in-house teams handle minor repairs confidently.

A broad parts network shortens lead times and prevents extended downtime waiting for components. Over the life of the unit, a maintenance-friendly design can save significant cost and keep operations on schedule.

Compatibility With Existing Systems

Mechanical units must integrate smoothly with transmissions, cooling systems, electrical components, and control interfaces. Compatibility issues can lead to costly modifications or performance limitations.

Checking mounting configurations, control requirements, and auxiliary support guarantees seamless installation.

Proper system alignment prevents inefficiencies and extends component lifespan. Compatibility planning is particularly valuable when upgrading or replacing existing units rather than building from scratch.

Early compatibility checks reduce surprises during installation and commissioning. Electrical load matching and software communication protocols are important in modern, sensor-driven systems.

Verifying cooling capacity and hose routing avoids heat-related performance losses after deployment.

Alignment with existing controls shortens training time for operators and technicians. When systems fit together cleanly, upgrades deliver value faster with fewer downstream adjustments.

Regulatory Compliance and Emissions Standards

Compliance with emissions and operational regulations affects where and how mechanical units can be used. Medium-duty systems often operate across multiple jurisdictions, making regulatory alignment important.

Units that meet current standards help avoid operational restrictions or retrofit requirements. Reviewing compliance certifications guarantees suitability for intended environments and protects long-term usability as regulations evolve.

Long-Term Value and Ownership Considerations

Selecting a medium-duty mechanical unit involves more than upfront cost. Long-term value includes reliability, service intervals, resale potential, and operating stability.

Buyers often weigh several practical considerations during evaluation:

- Expected service life under sustained workloads

- Availability of replacement parts over time

- Historical reliability data across similar applications

- Flexibility for future operational changes

Assessing total ownership value provides a clearer picture than purchase price alone. Units that deliver steady performance with manageable upkeep offer stronger returns across their operational lifespan.

Selecting a powerful medium-duty mechanical unit requires a balance of performance, durability, efficiency, and compatibility. Focusing on real-world operating conditions rather than isolated specifications leads to better outcomes and fewer compromises.

A thoughtful selection process supports reliable operation, predictable costs, and long-term operational confidence across a wide range of medium-duty applications.

Share this

Arthur Brown

Writer

A dad of 3 kids and a keen writer covering a range of topics such as Internet marketing, SEO and more! When not writing, he's found behind a drum kit.

previous

How to Create a Functional and Inviting Office Space for Your Team

next

Useful Data Regarding Commercial Grade Internal Combustion Units