business resources

Why Are High-Precision Bearings Essential for Aviation?

25 Sept 2025, 5:02 pm GMT+1

When we talk about aviation, it's easy to get caught up in the sheer power of engines and the elegant design of wings. Yet, where safety and performance are paramount, some of the most crucial components are often the most overlooked: high-precision bearings. These specialized parts are the silent workhorses that ensure every system runs seamlessly, from the roar of the engines to the nuanced movements of flight controls. Without them, the sophisticated machinery enabling flight simply wouldn't function as intended. So, what makes these tiny, vital components so incredibly important?

Key Takeaways

- At their core, high-precision bearings are bespoke components, manufactured to exacting standards and engineered to withstand the extreme speeds, heavy loads, and temperature shifts common in aviation.

- You'll find these bearings in nearly every critical aircraft system—powering smooth shaft rotation in engines, absorbing shock in landing gear, enabling fine-tuned adjustments in flight controls, and ensuring accuracy in avionics.

- The aerospace industry's demand for quality is non-negotiable; this means bearings must meet tough manufacturing standards, utilize advanced materials, and come with complete traceability and certification to guarantee reliability.

- Aviation bearings are built for resilience, designed to perform consistently in harsh environments marked by extreme temperatures, persistent vibrations, and corrosive agents without a hint of failure.

- Continuous innovation in materials and manufacturing is paving the way for even more advanced bearings, directly supporting the next generation of aviation technologies like electric and autonomous flight.

The Indispensable Role of Precision Bearings in Aviation

When you picture an airplane, powerful engines and sleek wings probably come to mind first. But tucked away within the complex machinery are components that, while less glamorous, are absolutely essential for flight. These are precision bearings. They are truly the unsung heroes that keep everything moving smoothly and safely, from the highest altitudes right down to the moment of touchdown.

Understanding Precision Bearings in Aerospace

Precision bearings aren't your everyday hardware. They are engineered to incredibly strict specifications, far surpassing what you'd encounter in standard machinery. Think of them as the Swiss watches of the mechanical world. Their design is tailored to handle extreme conditions—we're talking intense speeds, heavy loads, and constant vibrations—all while maintaining exceptionally tight operational clearances. It's this level of accuracy that sets them apart and makes them indispensable for the demanding world of aviation.

Why Precision is Paramount in Aviation

In the field of aviation, the margin for error is virtually zero. Every single part of an aircraft must function perfectly, and bearings are certainly no exception. Even a slight imperfection in a bearing can snowball into increased wear, diminished efficiency, or—in a worst-case scenario—a critical system failure. The reliability and safety of an aircraft hinge directly on the flawless performance of its precision bearings. This is precisely why aerospace engineers demand bearings that meet the most rigorous standards, which often far exceed general industry requirements.

A bearing failure in an aircraft isn't a minor hiccup; the consequences can range from negligible performance issues to truly catastrophic events. For this reason, the manufacturing and selection process for these components are subjected to intense scrutiny and uncompromising quality control.

The Unsung Heroes of Flight Systems

These essential bearings are integrated into nearly every critical system on an aircraft. They are the quiet workhorses that make possible:

- Engine Performance: They support rotating shafts in turbines and compressors, enabling them to spin at tens of thousands of revolutions per minute under immense heat and pressure.

- Landing Gear: They facilitate the smooth, high-force deployment and retraction of landing gear, absorbing shock and managing wildly varying loads.

- Flight Controls: They allow for the precise, low-friction movement of control surfaces like ailerons and elevators, which is absolutely critical for maneuvering the aircraft.

- Avionics and Navigation: They ensure the pinpoint accuracy of sensitive instruments, including gyroscopes and inertial navigation systems, where even the tiniest deviation could corrupt flight data.

Without these meticulously engineered components, modern aviation as we know it simply couldn't exist. They are the silent enablers of flight, ensuring that every aircraft operates with reliability and safety, regardless of the conditions.

Critical Applications of High-Precision Bearings

High-precision bearings are more than just components; they are the silent bedrock of complex aerospace systems. Their remarkable ability to perform flawlessly under the most extreme conditions makes them indispensable across a wide array of aircraft functions. Without them, the intricate choreography of flight would simply fall apart.

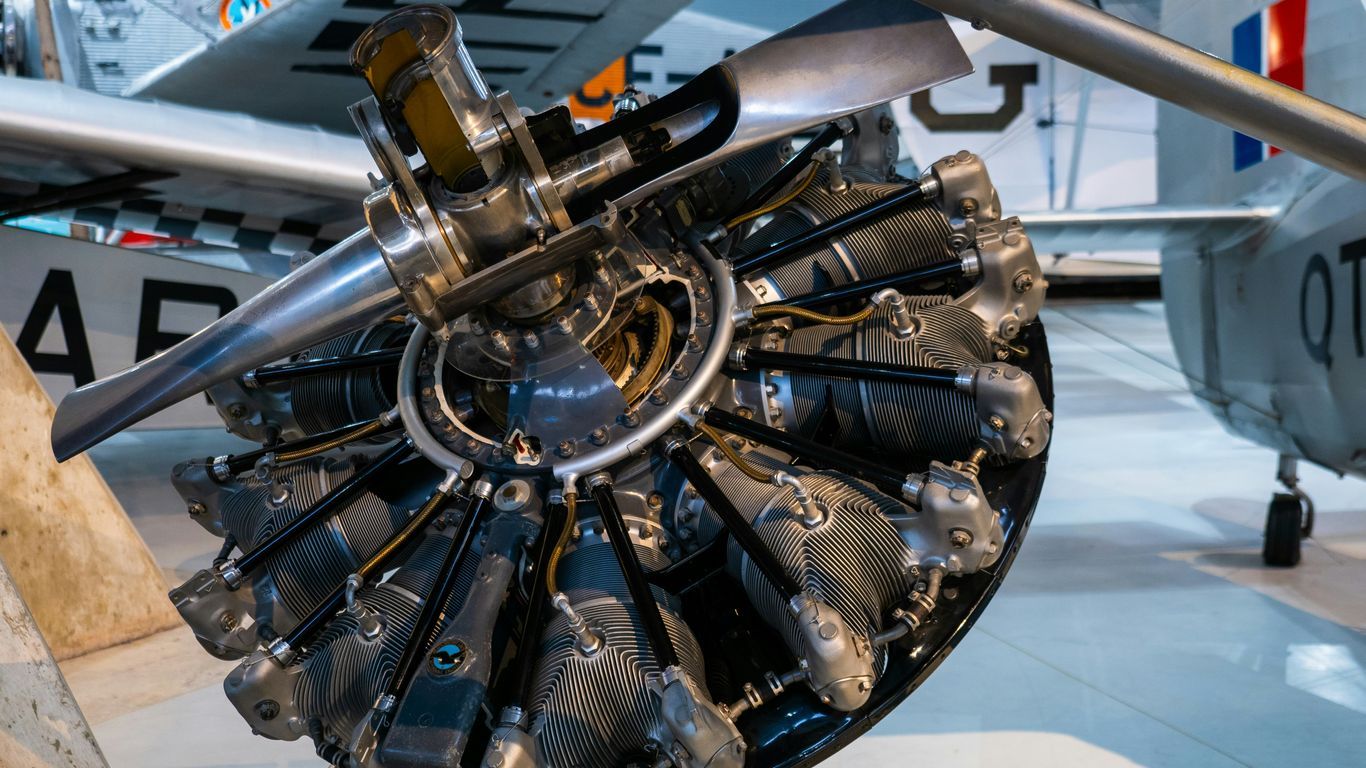

Aircraft Engine and Turbomachinery Performance

Aircraft engines operate under enormous stress, contending with punishing temperatures and pressures. Precision bearings are tasked with supporting the main shafts, allowing compressors and turbines to spin at tens of thousands of RPM without a hitch. They deftly manage significant axial and radial loads, keeping every part perfectly aligned and rotating smoothly. This seamless operation is absolutely key to fuel efficiency and the overall longevity of the engine.

Ensuring Reliability in Landing Gear Assemblies

Whenever an aircraft takes off or lands, its landing gear experiences rapid, high-force movements. The bearings within these assemblies have to absorb immense shocks, handle constantly shifting loads, and resist wear and tear. They support the aircraft's entire weight while facilitating fluid movement during taxiing, takeoff, and landing. The precision of these bearings has a direct and profound impact on the safety and reliability of these critical flight phases.

Facilitating Movement in Flight Control Systems

Key components like ailerons, rudders, and elevators all depend on precision bearings in their actuators. These bearings enable smooth, low-friction movement, accommodating various loads and low-torque rotations with ease. Because these systems are what dictate the aircraft's direction and stability, the accuracy and responsiveness that these bearings provide are paramount for safe and controlled flight.

Accuracy in Avionics and Instrumentation

Nowhere is precision more critical than in sensitive equipment like gyroscopes and inertial navigation systems, where even the slightest bearing error can cascade into incorrect flight data. Miniature precision bearings are employed here to maintain maximum accuracy. They minimize vibration and runout—imperfections in rotation—which is vital for precise geolocation and flight path calculations. The reliability of these instruments, and by extension the safety of the flight, rests heavily on the quality of these tiny, yet crucial, components.

Engineering Excellence for Aerospace Demands

Meeting Stringent Manufacturing Standards

Crafting components for an aircraft is a world away from assembling furniture from a box. The aerospace industry operates under some of the most demanding standards imaginable, and for good reason. When you're dealing with parts that must perform flawlessly thousands of feet in the air—or in the vacuum of space—there is simply no room for compromise. Manufacturers must adhere to highly specific protocols and processes to ensure every single bearing is perfect. This involves using specialized equipment, maintaining ultra-clean manufacturing environments, and conducting multiple layers of inspection. It's all geared toward one goal: guaranteeing these parts can withstand the harsh conditions they were designed for.

Advanced Materials and Design Considerations

So, what actually goes into an aerospace bearing? It’s not just your standard steel. Engineers are in a constant search for new materials that can elevate performance. Think about specialized ceramic compounds or advanced alloys capable of enduring extreme heat and wear without failing. The design itself is also a major focus. Bearings might be engineered to be smaller and lighter to reduce an aircraft's overall weight, yet they must remain strong enough to bear heavy loads. In some cases, they're treated with special coatings to prevent corrosion or to reduce friction even further. It’s a perpetual balancing act between performance, durability, and efficiency.

The Importance of Traceability and Certification

Every single part on an aircraft needs a documented history. That’s where traceability comes in. It means that every step, from the raw material that forms the bearing to the final finished product, is meticulously recorded. This creates a complete paper trail, so if a problem ever arises, engineers can trace it directly back to its source. Certification is the other side of this coin. Independent bodies verify that the bearings meet all required safety and performance standards. Put simply, without the proper certifications, a bearing cannot be installed on an aircraft. It’s a robust system designed to build trust and guarantee safety.

This level of precision and reliability in aerospace bearings doesn't happen by accident; it's the direct outcome of meticulous engineering, rigorous testing, and an unwavering commitment to quality that permeates the entire production process.

Here’s a brief look at some common types of bearings and what they do:

- Ball Bearings: Often found in engine components, these are used for high-speed rotation and lighter loads.

- Roller Bearings: Better suited for heavier loads and slower speeds, making them common in landing gear assemblies.

- Thrust Bearings: These are specifically designed to handle loads that are parallel to the axis of rotation, crucial in many types of rotating machinery.

- Hybrid Bearings: By combining materials like steel and ceramic, these bearings offer unique benefits, such as higher speed capabilities and superior resistance to heat and corrosion.

Bearing Technology for Extreme Aviation Environments

The environments where aircraft and spacecraft operate are nothing short of hostile. Just consider the immense forces and temperature swings involved. Bearings in these machines aren't just simple metal rings; they are sophisticated components engineered to manage incredible stress and maintain smooth operation. These specialized bearings are designed to perform reliably in situations where failure is simply not an option.

Withstanding High Speeds and Heavy Loads

Picture an aircraft engine spinning at tens of thousands of revolutions per minute, or the landing gear having to support the immense weight of an aircraft during touchdown. Bearings in these systems are meticulously designed to handle these extreme speeds and loads without faltering. For instance, bearings in jet engines support the main rotating shafts, allowing compressors and turbines to spin freely despite significant axial and radial forces. In a similar vein, landing gear bearings must absorb brutal shocks and handle dynamic forces during deployment and retraction, all while enabling efficient movement on the ground.

Performance Under Extreme Temperatures and Vibrations

Aerospace environments are defined by rapid and dramatic temperature fluctuations. A bearing might go from the sub-zero chill of high altitudes to the searing heat generated within an engine in a matter of moments. The materials and lubricants used in these bearings must resist breaking down under such conditions. They also need to endure constant vibrations that would quickly degrade less robust components. This is why hybrid bearings, often pairing ceramic balls with steel races, are so common—they can tolerate higher temperatures and dampen vibrations more effectively than their all-steel counterparts.

Corrosion Resistance in Demanding Conditions

It's not just physical forces; chemical threats are also a major concern. Aircraft and spacecraft can be exposed to a host of corrosive elements, from atmospheric moisture and de-icing fluids to aggressive hydraulic fluids and even the vacuum of space. Bearings must be fabricated from materials that naturally resist corrosion or be treated with protective coatings. This is vital for maintaining their structural integrity and operational performance over the entire lifespan of the aircraft. Materials like specialized stainless steels or ceramics are often selected for their inherent resilience to chemical attacks and environmental degradation.

The Future of Flight and Bearing Innovation

As the aerospace industry continues to rocket toward the future, the role of high-precision bearings is becoming even more critical. There's a relentless drive for lighter, stronger, and more efficient aircraft, and bearings are at the very heart of this evolution. Consider the new wave of electric aircraft, the push toward hypersonic travel, and the ongoing expansion of space exploration—each of these frontiers demands bearings that can perform under increasingly formidable conditions.

Advancements Driving Aerospace Bearing Technology

Several key areas are pushing the envelope for bearing technology in aviation. Materials science is a huge one; researchers are developing new alloys and composites that can handle higher temperatures and greater stresses while also being lighter. At the same time, manufacturing techniques are growing more sophisticated, allowing for tighter tolerances and more intricate designs. On top of that, there's a significant focus on predictive maintenance and "smart bearings" that can self-report their condition, helping to prevent failures before they ever occur.

The Growing Demand for High-Performance Bearings

The need for bearings that can operate reliably in these extreme environments is only intensifying. This includes:

- Higher Speeds: As engines and control systems become faster, bearings must be able to keep pace without overheating or premature wear.

- Extreme Temperatures: From the biting cold of high altitudes to the intense heat of propulsion systems, bearings must maintain their structural integrity.

- Increased Loads: Larger aircraft and more complex onboard systems mean that bearings are frequently subjected to greater forces.

- Reduced Friction: Minimizing friction remains a constant objective, as it has a direct and significant impact on fuel efficiency and overall performance.

Bearings in Next-Generation Aviation Systems

Looking to the horizon, precision bearings will be indispensable for several emerging aviation technologies. For electric aircraft, they will need to manage different load profiles and thermal challenges compared to traditional jet engines. In autonomous flight systems, the absolute reliability and precision of bearings in control surfaces and actuators are non-negotiable for safe operation. And in space, as missions grow more ambitious, bearings will confront even more extreme conditions, from the hard vacuum of space to the harsh environments of other celestial bodies. The continuous innovation in bearing design and materials is what directly enables these next great leaps in aviation.

In essence, the story of bearing development is inseparable from the story of aerospace itself. As aircraft become more complex and operate in more demanding conditions, the requirements placed on these small but vital components only intensify. This fosters a cycle of innovation where advancements in one area drive progress in another—ultimately leading to safer, more efficient, and more capable aircraft.

The Unseen Force Behind Flight

So, when we consider what enables flight, it's natural to focus on the visible power of engines and wings. But the truth is, it's the tiny, often-unseen components like precision bearings that keep the entire system operating flawlessly. These parts are engineered to withstand incredibly tough conditions—from extreme temperatures and heavy loads to phenomenal speeds. Without them, critical systems like flight controls and navigation simply couldn't function with the required accuracy. As aircraft technology advances, the demand for these high-quality bearings only continues to grow. They aren't just parts; they are the quiet enablers that help ensure every flight is safe and reliable, from takeoff to landing and even into the vastness of space.

Frequently Asked Questions

What makes aircraft bearings different from regular ones?

The key difference is their exceptional precision and resilience. Aircraft bearings are engineered to perform flawlessly under conditions—like extreme speeds, heavy loads, and drastic temperature shifts—where standard bearings would likely fail.

Why are precise bearings so important for airplane engines?

In an airplane engine, bearings are crucial for supporting the rapidly spinning components, like shafts and turbines, allowing them to move smoothly with minimal friction. This ensures the engine operates at peak efficiency, even under intense heat and pressure.

How do bearings help control an airplane's movement?

Bearings are vital in the actuators for control surfaces like ailerons and rudders. They permit these parts to move with ease and accuracy, which is what allows the pilot to steer the aircraft safely and execute smooth maneuvers.

What happens if a bearing in an airplane isn't precise enough?

An imprecise bearing can be a serious liability. It might cause components to wear out prematurely, reduce efficiency, or, in the worst-case scenario, lead to a critical system failure that could compromise the entire aircraft's safety.

Are there special bearings for different parts of an aircraft?

Absolutely. Different parts of an aircraft have unique demands. For example, engines require bearings that can handle high speeds and extreme heat, while landing gear needs robust bearings that can absorb heavy impacts and support the aircraft's weight.

What are the newest trends in aircraft bearings?

Innovation is constant. Engineers are leveraging stronger, lighter materials and more advanced designs to create bearings that last longer and operate more efficiently. The focus is on supporting the next generation of aircraft and spacecraft with enhanced performance and reliability.

Share this

Peyman Khosravani

Industry Expert & Contributor

Peyman Khosravani is a global blockchain and digital transformation expert with a passion for marketing, futuristic ideas, analytics insights, startup businesses, and effective communications. He has extensive experience in blockchain and DeFi projects and is committed to using technology to bring justice and fairness to society and promote freedom. Peyman has worked with international organisations to improve digital transformation strategies and data-gathering strategies that help identify customer touchpoints and sources of data that tell the story of what is happening. With his expertise in blockchain, digital transformation, marketing, analytics insights, startup businesses, and effective communications, Peyman is dedicated to helping businesses succeed in the digital age. He believes that technology can be used as a tool for positive change in the world.

previous

Boosting Customer Engagement Through Smart Business Practices

next

Understanding and Overcoming The Imposter Syndrome